This Article is extracted from Mike Holt’s Illustrated Guide to Understanding NEC® Requirements for Solar Photovoltaic Systems.

Understanding NEC Requirements for Solar Photovoltaic Systems, Based on the 2011 NEC

Click here to buy a copy or read more about it.

*Please note in the follwing extraction that blue underlined text indicates a 2014 NEC change.

(A) Alternating-Current PV System Grounding Requirements. For ac PV systems, a grounding electrode system must be provided in accordance with 250.50 through 250.60, with the ac grounding electrode conductor installed in accordance with 250.64.Figure 690–109

Figure 690–109

(B) Direct-Current PV System Grounding Requirements. For dc PV systems, a grounding electrode system in accordance with 250.166 for grounded systems, or 250.169 for ungrounded systems, must be provided. Figure 690–110

Figure 690–110

A common dc grounding-electrode conductor can service multiple inverters. Section 250.166 is used to size the common grounding electrode and the tap conductors. The tap conductors must be connected to the common grounding-electrode conductor by exothermic welding or with connectors listed as grounding and bonding equipment.

The ac grounding electrode system can be used for equipment grounding of inverters and for the ground-fault detection reference for un-grounded PV systems.

(C) PV Grounded System with Alternating-Current Power System. Grounded PV systems constructed of dc modules must have the dc system grounded by one of the following methods:

(1) Separate dc Electrode. A grounding electrode conductor run from the marked dc GEC point at the inverter to the separate dc grounding electrode sized no smaller than the largest ungrounded dc conductor, but no smaller than 8 AWG [250.166(B)]. The dc grounding electrode must be bonded to the ac grounding electrode with a bonding jumper sized to the larger of the dc grounding electrode conductor [250.166] or ac grounding electrode conductor [250.66]. Figure 690–111

Figure 690–111

(2) Alternating-Current Grounding Electrode. A grounding electrode conductor sized in accordance with 250.166 must be run from the marked dc GEC point at the inverter to the ac grounding electrode. Figure 690–112

Figure 690–112

Where an ac grounding electrode isn’t accessible, the dc grounding electrode conductor must terminate to the ac grounding electrode conductor with a connector listed as grounding and bonding equipment. 690–113

Figure 690–113

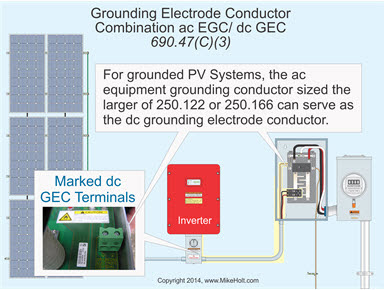

(3) Combination ac Equipment Grounding Conductor/dc Grounding Electrode Conductor. For grounded PV Systems, the ac equipment grounding conductor sized to the larger of 250.122 or 250.166 can serve as both the ac circuit equipment grounding conductor and dc grounding electrode conductor. Figure 690–114

Figure 690–114

Figure 690–115

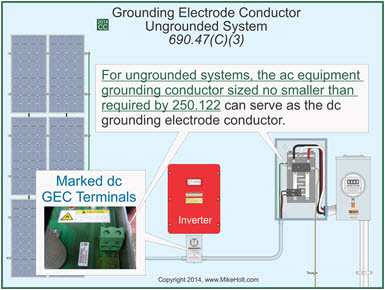

For ungrounded systems, the ac equipment grounding conductor sized no smaller than required by 250.122 based on the rating of the ac circuit overcurrent protection device can serve as both the ac circuit equipment grounding conductor and dc grounding electrode conductor.Figure 690–116

Figure 690–116

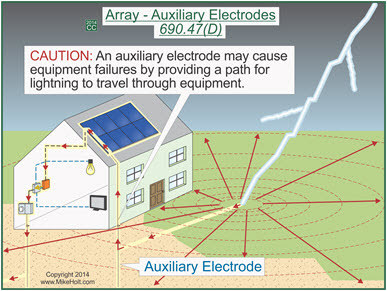

(D) Auxiliary Electrode for Array. A dc grounding electrode conductor from the array structure sized in accordance with 250.166 must be connected to a grounding electrode that complies with 250.52 and 250.54.

The metal structure of a ground- or pole-mounted PV array can serve as the grounding electrode if it complies with 250.52.

Roof-mounted PV arrays can use the metal frame of a building or structure as the electrode if it meets 250.52(A)(2). Figure 690–117

Figure 690–117

Ex No. 1: An array grounding electrode(s) isn’t required where the load served by the array is integral with the array.

Ex No. 2: An additional array grounding electrode(s) isn’t required if located within 6 ft of the premises wiring electrode.

Figure 690–118

| |||

|

Comments

Post a Comment